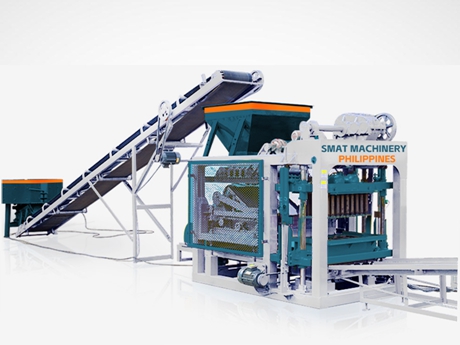

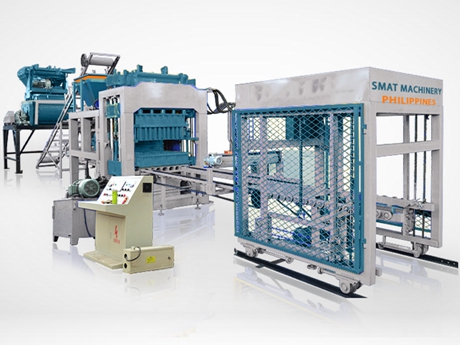

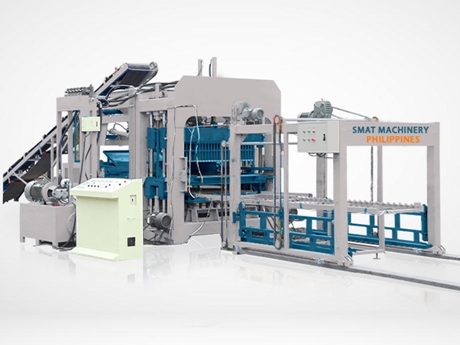

- Block Machine

Model: QT4-25

Model:QT3-15

Model: QT4-15

Model: QT5-15

Model: QT6-15

Model: QT8-15

Model: QT10-15

Description

SMAT concrete block machine for sale can produce various high-strength wall blocks, hollow blocks, paving blocks and slope protection blocks etc. With our automated process, brick making machines can transform raw materials into high quality, consistent specification bricks.

Hot Sale

SMAT concrete block machine

QT4-24

SMAT has been serving a large number of concrete mixing plant customers in the world. We have a wide range of mixing plants with customized options for capacity, mixing efficiency, feeding speed and more depending on your needs.

- Model: HZS25

- Hourly Capacity: 30 TPH

- Output Size: S1, 3/8, 3/4, G1

- Power Supply: Electricity or Genset

QT4-15

SMAT has been serving a large number of concrete mixing plant customers. We have a wide range of mixing plants with customized options for capacity, mixing efficiency, feeding speed and more depending on your needs.

- Model: HZS25

- Hourly Capacity: 30 TPH

- Output Size: S1, 3/8, 3/4, G1

- Power Supply: Electricity or Genset

QT6-15

SMAT has been serving a large number of concrete mixing plant customers. We have a wide range of mixing plants with customized options for capacity, mixing efficiency, feeding speed and more depending on your needs.

- Model: HZS25

- Hourly Capacity: 30 TPH

- Output Size: S1, 3/8, 3/4, G1

- Power Supply: Electricity or Genset

Specification

| Model | QT4-24 | QT3-15 | QT4-15 | QT5-15 | QT6-15 | QT8-15 | QT10-15 |

| Molding Cycle | 24 | 15 | 15s | 15s | 15s | 15s | 15s |

| Vibration Frequency | 3500r/min | 4500r/min | 4600r/min | 2800-4500r/min | 4500-5100r/min | 2800-4500r/min | 2800-4500r/min |

| Exciting Power | 50kn | 50kn | 55kn | 60kn | 65kn | 85kn | 110kn |

| Overall Power | 20.6kw | 20.75kw | 27.5KW | 32kw | 28.75kw | 51kw | 67KW |

| Pallet Size | 850x550mm | 680x550mm | 1020x570mm | 1100x550mm | 850x680mm | 950x900mm | 950x900mm |

| Overall Dimension | 5600x2240x2400mm | 5990x4260x2620mm | 7310*2500*2810mm | 7310x26000x2890mm | 7450x24500x3050mm | 8300x28000x2900mm | 9350*3000*2900mm |

Advantage

SMAT Concrete Block Machine for Sale

Related Cases

SMAT Concrete block machine for sale

What SMAT Would Do After Making Oder

Until now, our block making machines have been widely used in construction, roads, bridges and other engineering projects by customers around the world.

Quality Service Before Shipping

SMAT takes every order seriously. Every step of the process is checked by special person. Every important component is pre-tested before shipment, especially the mixer machine. It also ensures that free spare parts are given to the customer to avoid any possible accidents.

01

Packing and shipping

SMAT has nearly 30 years of export experience. The self loading mixer manufactured by us have been exported to different countries. The Concrete Batching Plant will be packed and loaded in our factory, and then be shipped to our clients safe and sound.

02

Technical Service

SMAT provides engineers with on-site installation guidance, commissioning, and training services. SMAT engineers have rich experience in mechanical, electrical, and civil engineering. Proficiency in English and Chinese, the common languages, ensures smooth communication with operators on site.

03

Service

- China SMAT is in Zhengzhou City. Make sure timely and rapid response to customer needs.

- Engineers team are always available for on-site installation guidance, commissioning, and training services.

- SMAT provides regular visiting to clients sites, thus can promptly correct improper operations.

- Adequate stock of original spare parts to ensure the smooth operation of the project.

- Free customized product appearance color and Logo, provide ODM support.

- VIP groups are created for customers. If you have any questions, feel free to give feedback.

- 7*24 hours online free consulting service, including quotation, 2-3 sets of program design, AutoCAD & 3D drawings, and site planning.

You May Need

SMAT provides various concrete machines for sale, feel free to contact SMAT team.