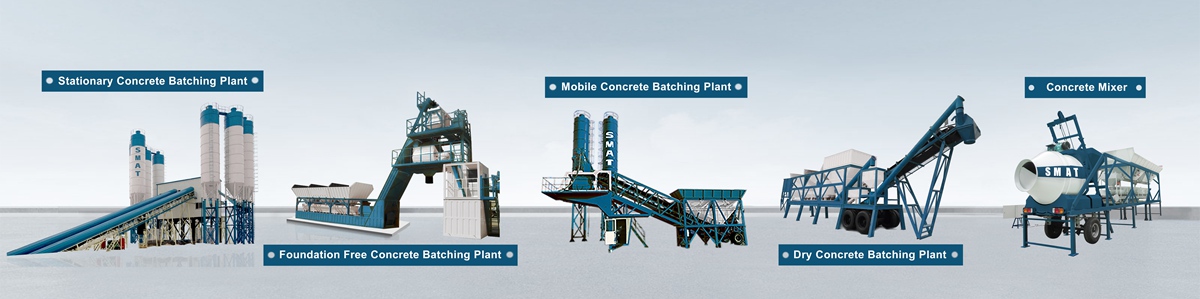

- Stationary Type

- Foundation-Free Type

- Dry Mix Type

- JS Concrete Mixer

Model:HZS25

Productivity: 25m³/h

Mixer Model: JS500

Rated Input Volume: 800L

Model:HZS35

Productivity: 35m³/h

Mixer Model: JS750

Rated Input Volume: 1200L

Model:HZS50

Productivity: 50m³/h

Mixer Model: JS1000

Rated Input Volume: 1600L

Model:HZS60

Productivity: 60m³/h

Mixer Model: JS1000

Rated Input Volume: 1600L

Model:HZS75

Productivity: 75m³/h

Mixer Model: JS1500

Rated Input Volume: 2400L

Model:HZS90

Productivity: 90m³/h

Mixer Model: JS1500

Rated Input Volume: 2400L

Model:HZS120

Productivity: 120m³/h

Mixer Model: MAO3000/2000

Rated Input Volume: 3000L

Model:HZS180

Productivity: 180m³/h

Mixer Model: MAO4500/3000

Rated Input Volume: 4500L

Model: FHZS-25

Productivity: 25m³/h

Mixer Model: JS500

Mixer Power: 18.5kw

Model: FHZS-35

Productivity: 35m³/h

Mixer Model: JS750

Mixer Power: 30kw

Model: FHZS-50

Productivity: 50m³/h

Mixer Model: JS100

Mixer Power: 2*18.5kw

Model: FHZS-60

Productivity: 60m³/h

Mixer Model: JS1000

Mixer Power: 2*18.5kw

Model: FHZS-75

Productivity: 75m³/h

Mixer Model: JS1500

Mixer Power: 2*30kw

Model: FHZS-90

Productivity: 90m³/h

Mixer Model: JS1500

Mixer Power: 2*30kw

Model: FHZS-120

Productivity: 120m³/h

Mixer Model: MAO3000/2000(SICOMA)

Mixer Power: 2*37kw

Model: FHZS-180

Productivity: 180m³/h

Mixer Model: MAO4500/3000(SICOMA)

Mixer Power: 2*55kw

Model: Dry Concrete Batching Plant

Model: Dry Concrete Batching Plant

Model: Dry Concrete Batching Plant

Model: Dry Concrete Batching Plant

Model: JS500

Discharging Capacity: 500L

Charging Capacity: 800L

Productivity: ≥25m³/h

Model: JS750

Discharging Capacity: 750L

Charging Capacity: 1200L

Productivity: ≥37.5m³/h

Model: JS1000

Discharging Capacity:1000L

Charging Capacity: 1600L

Productivity: ≥50m³/h

Model: JS1500

Discharging Capacity: 1500L

Charging Capacity: 2400L

Productivity: ≥75m³/h

Model: JS2000

Discharging Capacity: 2000L

Charging Capacity: 3200L

Productivity: ≥100m³/h

Model: JS3000

Discharging Capacity: 3000L

Charging Capacity: 4800L

Productivity: ≥150m³/h

Description

SMAT has been serving a large number of concrete batching plant customers in the world. We have a wide range of mixing plants with customized options for capacity, mixing efficiency, feeding speed, and more depending on your needs. Our customers cover countries like Philippines, Malaysia, UAE, Saudi Arabia, Azerbaijan, Guyana, Georgia, etc. Please feel free to contact us.

Type of SMAT Concrete Batching Plant

Hot Sale

Stationary Type HZS60

HZS60 is a hot seller because this model will not overproduce or fail to meet various demands. It can either make concrete for your project or be the foundation for your next step in selling commercial concrete.

- Model: HZS60

- Productivity: 60m³/h

- Mixer Model: JS1000

- Rated Input Volume: 1600L

Stationary Concrete Batching Plant Specification

| Model | HZS25 | HZS-35 | HZS-50 | HZS-60 | HZS-75 | HZS-90 | HZS-120 | HZS-180 |

| Theoretical Productivity (m³/h) | 25 | 35 | 50 | 60 | 75 | 90 | 120 | 180 |

| Mixer Model (Mixer Output L) | JS500 | JS750 | JS1000 | JS1000 | JS1500 | JS1500 | MAO3000/2000(SICOMA) | MAO4500/3000(SICOMA) |

| Mixer Power (kW) | 18.5 | 30 | 2×18.5 | 2×18.5 | 2×30 | 2×30 | 2×37 | 2×55 |

| Mixing Cycle Period (s) | 72 | 72 | 72 | 60 | 72 | 60 | 60 | 60 |

| Rated Input Volume (Model of Batching Machine L) | 800 | 1200 | 1600 | 1600 | 2400 | 2400 | 3000 | 4500 |

| Standard Aggregate Bin Capacity (m³) | 3×3 | 3×5 | 3×8 | 4×7 | 3×12 | 4×15 | 4×15 | 4×20 |

| Category of Aggregate | 2/3 | 2/3/4 | 3/4 | 4/5 | 4/5 | 4/5 | 4/5/6 | 4/5/6 |

| Overall Weight (ton) | ≈15 | ≈18 | ≈23 | ≈40 | ≈30 | ≈68 | ≈93 | ≈101 |

| Installation Power (kW) | ≈65 | ≈75 | ≈100 | ≈110 | ≈140 | ≈160 | ≈220 | ≈290 |

Mobile Type YHZS35

YHZS35 is SMAT's hottest-selling concrete batching plant model. It meets the needs of most customers for your house construction and road construction projects. We have some site you can see. Please contact us to arrange the time.

- Model: YHZS35

- Productivity: 35m³/h

- Discharging Volume: 1000L

- Feeding Volume: 1600L

Mobile Concrete Batching Plant Specification:

| Parameters/Model | YHZS-25 | YHZS-35 | YHZS-60 | YHZS-90 |

| Theoretical Productivity (m³/h) | 25 | 35 | 60 | 90 |

| Mixer Discharging Volume (L) | 500 | 750 | 1000 | 1500 |

| Mixer Feeding Volume (L) | 800 | 1200 | 1600 | 2400 |

| Mixer Motor Power (kW) | 18.5 | 30 | 18.5×2 | 30×2 |

| Discharging Height (m) | 3.8 | 4.1 | 4.1 | 4.1 |

| Aggregate Material Quantity (m3) | 3×3 | 5×3 | 8×3 | 12×3 |

| Cycle Period (s) | 60 | 60 | 60 | 60 |

| Max. Aggregate Size (mm) | 80/60 | 80/60 | 80/60 | 80/60 |

| Cement Silo (t) (optional) | 50×1 | 50×1 | 100×1 | 100×1 |

| Aggregate Weighing Accuracy | ±2% | ±2% | ±2% | ±2% |

| Powder Material Weighing Accuracy | ±1% | ±1% | ±1% | ±1% |

| Water Weighing Accuracy | ±1% | ±1% | ±1% | ±1% |

| Additive Weighing Accuracy | ±1% | ±1% | ±1% | ±1% |

| Installation Power (kW) | ≈65 | ≈75 | ≈100 | ≈140 |

| Traction Type | Semi-trailer | |||

| Control Mode | Full Automatic Computer PLC Control | |||

| Power Supply | 220V/415V/440V/380V/, 50HZ/60HZ, 3Phase | |||

Foundation Free Concrete Batching Plant FHZS60

Foundation-free concrete batching plants are designed to be easily transported. They can be moved from one location to another quickly and efficiently, making them ideal for projects that require frequent relocations.

- Model: FHZS60

- Productivity: 60m³/h

- Mixer Model: JS1000

- Mixer Power: 2*18.5kw

Foundation-Free Batching Plant Specification

| Model | FHZS25 | FHZS-35 | FHZS-50 | FHZS-60 | FHZS-75 | FHZS-90 | FHZS-120 | FHZS-180 |

| Theoretical Productivity (m³/h) | 25 | 35 | 50 | 60 | 75 | 90 | 120 | 180 |

| Mixer Model (Mixer Output L) | JS500 | JS750 | JS1000 | JS1000 | JS1500 | JS1500 | MAO3000/2000(SICOMA) | MAO4500/3000(SICOMA) |

| Mixer Power (kW) | 18.5 | 30 | 2×18.5 | 2×18.5 | 2×30 | 2×30 | 2×37 | 2×55 |

| Mixing Cycle Period (s) | 72 | 72 | 72 | 60 | 72 | 60 | 60 | 60 |

| Rated Input Volume (Model of Batching Machine L) | 800 | 1200 | 1600 | 1600 | 2400 | 2400 | 3000 | 4500 |

| Standard Aggregate Bin Capacity (m³) | 3×3 | 3×5 | 3×8 | 4×7 | 3×12 | 4×15 | 4×15 | 4×20 |

| Category of Aggregate | 2/3 | 2/3/4 | 3/4 | 4/5 | 4/5 | 4/5 | 4/5/6 | 4/5/6 |

| Overall Weight (ton) | ≈15 | ≈18 | ≈23 | ≈40 | ≈30 | ≈68 | ≈93 | ≈101 |

| Installation Power (kW) | ≈65 | ≈75 | ≈100 | ≈110 | ≈140 | ≈160 | ≈220 | ≈290 |

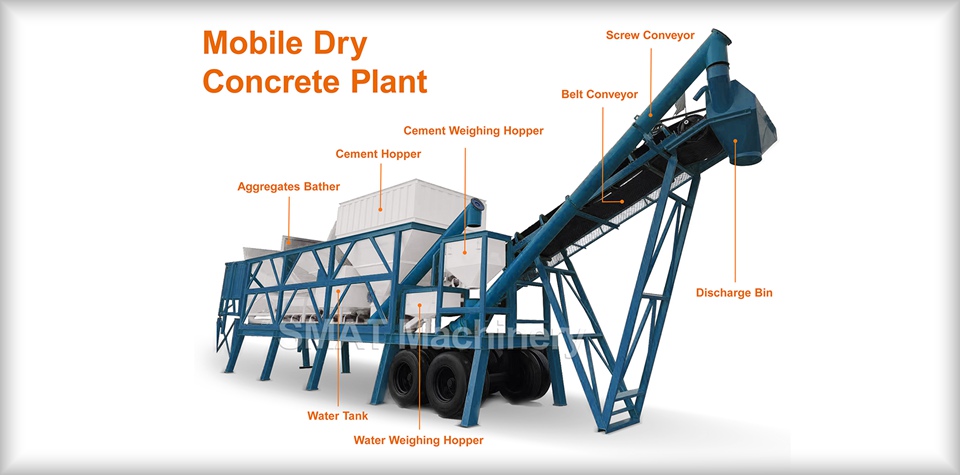

Dry Concrete Batching Plant

In a dry concrete batching plant, ingredients such as aggregate, cement and additives are transported to an aggregate silo or directly into a tanker for batching. Water is added to it to produce concrete.

Dry Concrete Batching Plant

In a dry concrete batching plant, ingredients such as aggregate, cement and additives are transported to an aggregate silo or directly into a tanker for batching. Water is added to it to produce concrete.

JZC/JZM Concrete Mixer Machine

These series concrete mixer can mix plastic and dry-hard concrete, forward stirring andreversal discharging. lt is combinedto medium & small scale batching plant with batching machine ,applies to constructionsite, road, bridge and hydropower etc., especially for urban residential construction.

PLD Concrete Batching Machine

SMAT's PLD range of batch machine has a wide range of models for you to choose from. Individual weighing or centralised weighing, fully automatic operation for customer convenience.

Related Cases

Please check more about SMAT concrete batching plant case all over the world.

The Components of SMAT Concrete Batching Plant

SMAT concrete batching plant mainly consists of five main systems: mixer, material weighing system, conveying system, storage system, and control system. If you want to know more about the basic components, SMAT will introduce them to you as follows.

Concrete Mixer

SMAT concrete batching plant introduces advanced mixing technology and is equipped with an efficient mixing system to ensure uniform and stable quality of concrete. It has high production efficiency, strong mixing ability, and strong flexibility.

01

Aggregates Batcher

Equipped with an intelligent management system to realize real-time monitoring and data analysis of the production process. It helps to adjust production parameters in time and improve production efficiency.

02

Control System

Equipped with an automated control system, it can realize fully automatic production operations, improve production efficiency, and reduce labor costs

03

Conveying System

Use an imported lubrication system and shaft drive system. All components have reliable quality and stable performance.

04

-

-

Cement Bin

Use wear-resistant materials. The support frame and aggregate bin are designed to be strong and durable for longer service life. The structural design is reasonable and the maintenance is gradual. Reduce downtime and increase production efficiency

05

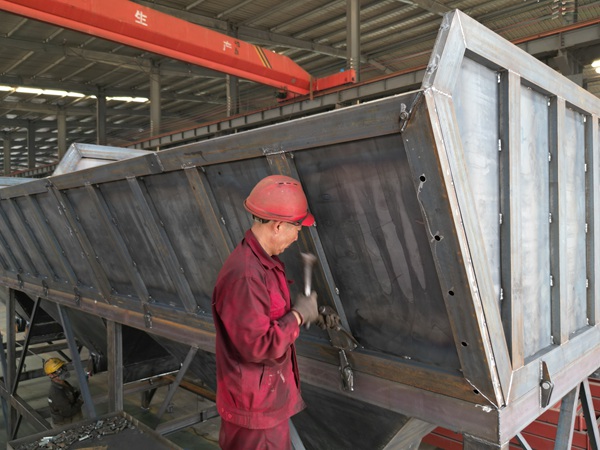

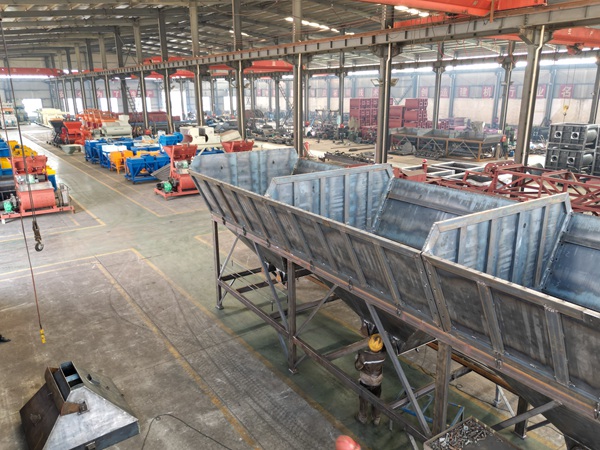

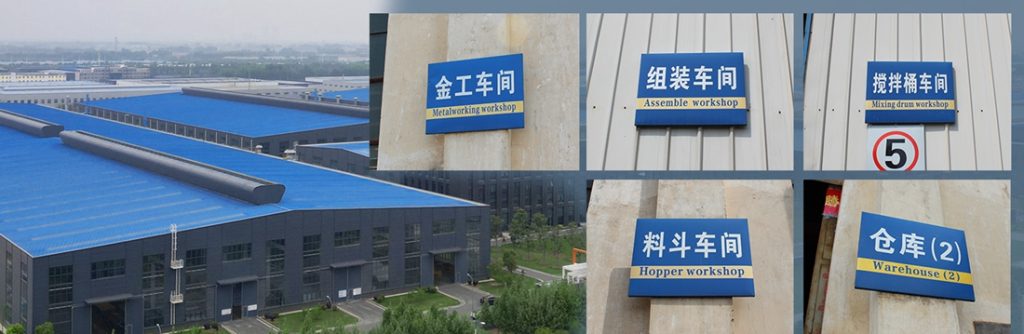

SMAT Factory Show

SMAT was established in 1988, specializing in one-stop service for design, R&D, production, sales, and installation of concrete machinery and mining machinery. From the first machine off the production line to today’s products all over the world, we always believe that providing high-quality products and timely efficient after-sales service is the key to business development.

Currently, SMAT has several production plants in China. The total area is 300,000 square meters with 28 perfect production lines. As a top manufacturer of machinery for the construction industry, SMAT focuses on making innovative technologies, manufacturing better quality products, and providing comprehensive solutions for the projects of our global customer partners. Our products have been exported to more than 80 countries and we have set up service stations in many countries.

What SMAT Would Do After Confirm Order

SMAT concrete batching plant is a mechanized, automated, high-efficiency, and integrated concrete mixing equipment that is widely used in concrete production projects with large quantities of work and long construction periods. SMAT has successfully exported to more than 80 countries with our technological innovation and R&D strength in the field of concrete machinery, as well as the high performance and versatility of products.

Quality Service Before Shipping

SMAT takes every order seriously. Every step of the process is checked by special person. Every important component is pre-tested before shipment, especially the mixer machine. It also ensures that free spare parts are given to the customer to avoid any possible accidents.

01

Packing and shipping

SMAT has nearly 30 years of export experience. The concrete batching plants manufactured by us have been exported to different countries. The Concrete Batching Plant will be packed and loaded in our factory, and then be shipped to our clients safe and sound.

02

Technical Service All over the World

SMAT provides engineers with on-site installation guidance, commissioning, and training services. And SMAT engineers have rich experience in mechanical, electrical, and civil engineering. Proficiency in English and Chinese, the common languages, ensures smooth communication with operators on site.

03

Advantage

SMAT Concrete Batching Plant:

Service

- China SMAT is in Zhengzhou City. Make sure timely and rapid response to customer needs.

- Engineers team are always available for on-site installation guidance, commissioning, and training services.

- SMAT provides regular visiting to clients sites, thus can promptly correct improper operations.

- Adequate stock of original spare parts to ensure the smooth operation of the project.

- Free customized product appearance color and Logo, provide ODM support.

- VIP groups are created for customers. If you have any questions, feel free to give feedback.

- 7*24 hours online free consulting service, including quotation, 2-3 sets of program design, AutoCAD & 3D drawings, and site planning.

Specification

Concrete Batching Plant & Self Loading Mixer

You May Need

SMAT provide varies concrete machines for your construction project