- Phone/Text: +8618137163949

- Email: [email protected]

-

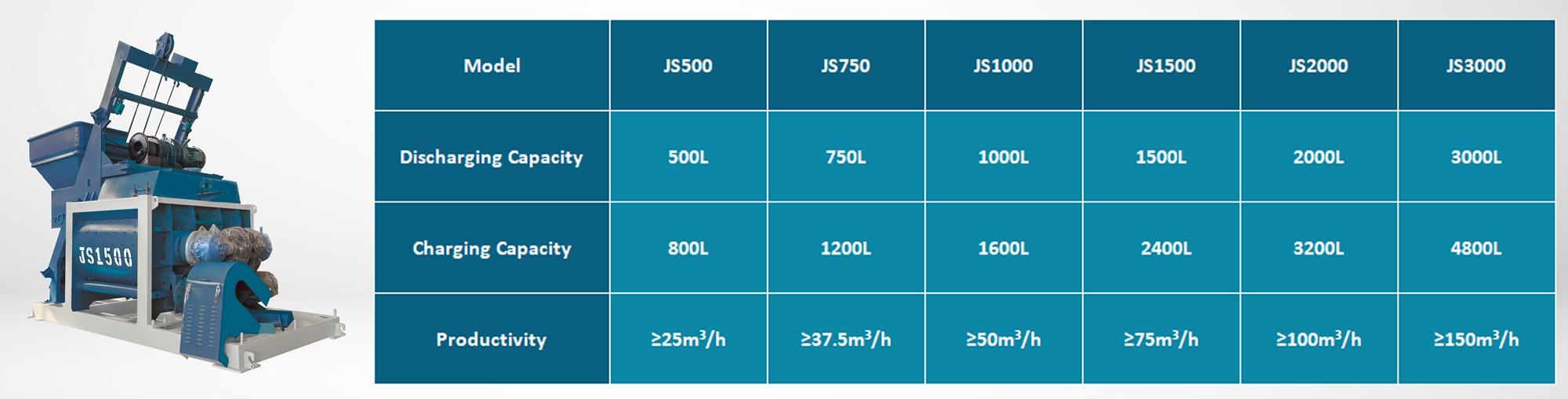

Description SMAT has been serving a large number of concrete batching plant customers. Hot Sale Specification Items JS500 JS750 JS1000 JS1500 JS2000 JS3000 Discharging Capacity…

SMAT has been serving a large number of concrete batching plant customers.

Model: JS750

Discharging Capacity: 750L

Charging Capacity: 1200L

Productivity: ≥37.5m³/h

Model: JS1000

Discharging Capacity:1000L

Charging Capacity: 1600L

Productivity: ≥50m³/h

Model: DHZS-25

Productivity: 25m³/h

Model: DHZS-35

Productivity: 35m³/h

| Items | JS500 | JS750 | JS1000 | JS1500 | JS2000 | JS3000 | ||

| Discharging Capacity | 500L | 750L | 1000L | 1500L | 2000L | 3000L | ||

| Charging Capacity | 800L | 1200L | 1600L | 2400L | 3200L | 4800L | ||

| Productivity | ≥25m³/h | ≥37.5m³/h | ≥50m³/h | ≥75m³/h | ≥100m³/h | ≥150m³/h | ||

| mm(Aggregate/Riverstone)Maximum size of aggregate | 80/60 | 80/60 | 80/60 | 80/60 | 80/60 | 100/120 | ||

| Blade | Rotate speed | 35r/mir | 31r/mir | 25.5r/mir | 25.5r/min | 23r/min | 21r/min | |

| quantity | 2×7 | 2×7 | 2×7 | 2×8 | 2×9 | 2×10 | ||

| Main motor | Model | Y180M-4 | Y200L-4 | Y225S-4 | Y200L-4 | Y225S-4 | Y250M-4 | |

| Power | 18.5KW | 30KW | 37KW | 30KW×2 | 37KW×2 | 55KW×2 | ||

| Hoisting motor | Model | YEZ132S-4-B5 | YEZ132S-4-B5 | YEZ160S-4 | YEZ180L-4 | YEJ180S-4 | ||

| Power | 5.5KW | 7.5KW | 15KW | 18.5KW | 22KW | |||

| Water Pump motor | Model | 50DW820-8A | 65DWB35-5 | KQW65-100 I | KQW65-100 I | CK65-20L | ||

| Power | 0.75KW | 1.1KW | 3kw | 3kw | 4kw | |||

| Bucket Hoisting speed | 18m/min | 18m/min | 21.9m/min | 23m/min | 26.8m/min | |||

| Overall Dimension | Transportation Status | 3050x2300x2680mm | 3650x2600x2890mm | 4640×2250×2250mm | 5058×2250×2440mm | 5860×2250×2735mm | ||

| Working Status | 4461x3050x5225mm | 4951x3650x6225mm | 8765×3436×9540mm | 9645×3436×9700mm | 10720×3870×10726mm | |||

| Total weight | 4000kg | 5500kg | 8700kg | 11130kg | 15000kg | |||

| Discharging height | 1500mm/3800mm | 1500mm/3800mm | 4000mm | 4000mm | 4000mm | |||

SMAT concrete batching plant mainly consists of five main systems: mixer, material weighing system, conveying system, storage system, and control system. If you want to know more about the basic components, SMAT will introduce them to you as follows.

SMAT concrete batching plant introduces advanced mixing technology and is equipped with an efficient mixing system to ensure uniform and stable quality of concrete. It has high production efficiency, strong mixing ability, and strong flexibility.

01

Equipped with an intelligent management system to realize real-time monitoring and data analysis of the production process. It helps to adjust production parameters in time and improve production efficiency.

02

Equipped with an automated control system, it can realize fully automatic production operations, improve production efficiency, and reduce labor costs

03

Use an imported lubrication system and shaft drive system. All components have reliable quality and stable performance.

04

Use wear-resistant materials. The support frame and aggregate bin are designed to be strong and durable for longer service life. The structural design is reasonable and the maintenance is gradual. Reduce downtime and increase production efficiency

05

Please check more about SMAT concrete batching plant case.

SMAT concrete batching plant is a mechanized, automated, high-efficiency, and integrated concrete mixing equipment that is widely used in concrete production projects with large quantities of work and long construction periods. SMAT has successfully exported to more than 80 countries with our technological innovation and R&D strength in the field of concrete machinery, as well as the high performance and versatility of products.

SMAT takes every order seriously. Every step of the process is checked by special person. Every important component is pre-tested before shipment, especially the mixer machine. It also ensures that free spare parts are given to the customer to avoid any possible accidents.

01

SMAT has nearly 30 years of export experience. The concrete batching plants manufactured by us have been exported to different countries. The Concrete Batching Plant will be packed and loaded in our factory, and then be shipped to our clients safe and sound.

02

SMAT provides various concrete machines for your construction project