- Phone/Text: +8618137163949

- Email: [email protected]

-

It can be independent of the construction site and is suitable for small and medium-sized projects.

SMAT concrete trailer pumps can be independent of the construction site and is suitable for large projects.

Model:HBT-80R

Max Output: 84/45(m³/h)

Power: 176KW

Power Supply: Diesel Engine

Model: HBT80-E

Max Output: 86/45(m³/h)

Power: 90KW

Power Supply: Electric Engine

The parts used in SMAT concrete pumps are all top brands. Only by strictly demanding every part and link, SMAT can deliver the most satisfactory machine to customers.

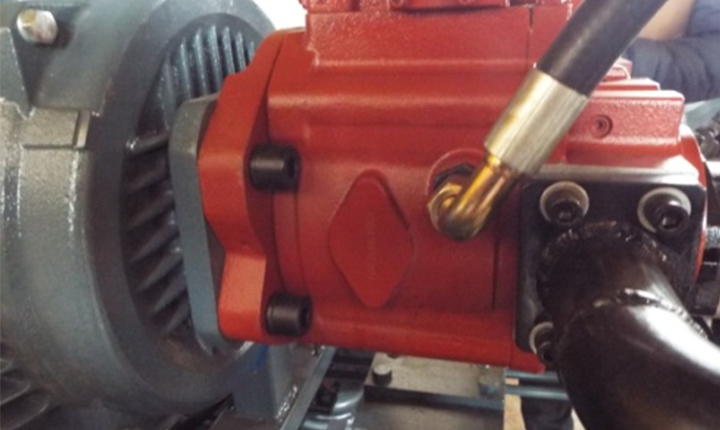

We adopt double pumps and double-circuit open hydraulic systems. The main pump oil circuit and S-valve swing oil circuit are independent of each other, so it is easy to determine the source of failure and eliminate it in time

01

Fast signaling and simultaneous control of multiple circuits used to directly control motors or other electrical actuators. Work efficiently.

02

It has an automatically enhanced lubrication system to ensure effective lubrication during the operation.

03

Good elasticity and high abrasion resistance. Free with order.

04

Adopt modular design and easy installation. It can be customized according to engineering needs to improve the adaptability and flexibility of the equipment.In case machine parts fail, regional debugging can be used to solve the problem and avoid time costs.

05

We adopt double pumps and double-circuit open hydraulic systems. The main pump oil circuit and S-valve swing oil circuit are independent of each other, so it is easy to determine the source of failure and eliminate it in time.

06

SMAT uses the world-famous brand engine, more stable quality, and longer service life

07

Wireless remote control operation is more safe and more convenient for operators. With the automated control system as well as intelligent operation, it can save time for training.

08

Our products are shipped to various sites of road construction, bridge construction, and real estate construction all over the world.

SMAT takes every order seriously. Every step of the process is checked by special person. Every important component is pre-tested before shipment, especially the mixer machine. It also ensures that free spare parts are given to the customer to avoid any possible accidents.

01

SMAT has nearly 30 years of export experience. The concrete pump manufactured by us have been exported to different countries. The Concrete Batching Plant will be packed and loaded in our factory, and then be shipped to our clients safe and sound.

02

SMAT provides engineers with on-site installation guidance, commissioning, and training services. SMAT engineers have rich experience in mechanical, electrical, and civil engineering. Proficiency in English and Chinese, the common languages, ensures smooth communication with operators on site.

03

SMAT provides varies concrete machines for your project.

Diesel Engine Concrete Trailer Pump

| Items | HBT-80R |

| Max. theo. concrete output(L./H) | 84/45m³/h |

| Max.concrete pumping pressure(H./L.) | 43785MPa |

| Distribution valve type | S Valve |

| Concrete cylinder diameter X stroke | Φ200X1800mm |

| Hopper capacity x feeding height | 800/1400L/mm |

| Outlet diameter | Φ180mm |

| Diesel engine model | Wechai |

| Electrical engineering power | 176KW |

| Rotate speed | 2200r/min |

| Pumping system pressure | 32MPa |

| Mixing system pressure | 43624MPa |

| Capacity of oil tank | 580L |

| Max. Theoretical Vertical/Horizontal Conveying Distance | 200/800m |

| Max. aggregate diameter | Slick/scree:40/50mm |

| Inside diameter of delivering pipe | Φ125mm |

| Dimensions: length×width×height | 6300x2100x2350mm |

| Total weight | 6900kg |

| Items | HBT-80E |

| Max. theo. concrete output(L./H) | 86/45m³/h |

| Max.concrete pumping pressure(H./L.) | 16/11MPa |

| Distribution valve type | S Valve |

| Concrete cylinder diameter X stroke | Φ200X1800mm |

| Hopper capacity x feeding height | 800/1100L/mm |

| Outlet diameter | Φ180mm |

| Electrical engineering power | 90KW |

| Rotate speed | 1480r/min |

| Pumping system pressure | 32MPa |

| Mixing system pressure | 14MPa |

| Capacity of oil tank | 580L |

| Max. Theoretical Vertical/Horizontal Conveying Distance | 200/800L |

| Max. aggregate diameter | Slick/scree:40/50mm |

| Inside diameter of delivering pipe | Φ125mm |

| Dimensions: length×width×height | 6300x2100x2250mm |

| Total weight | 6300kg |